Ford Announces Plans for Cheaper Electric Truck

Ford Announces Plans for Cheaper Electric Truck

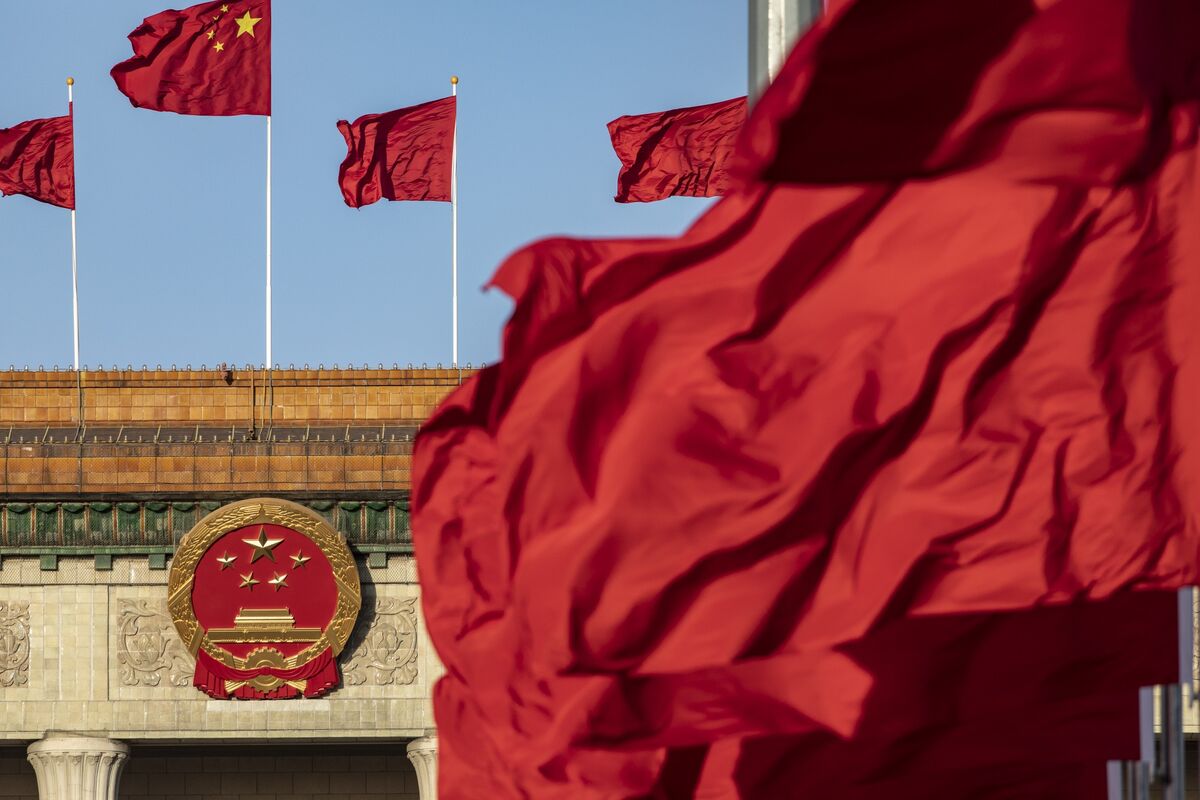

Ford has recently announced its plans to retool its Louisville Assembly Plant to focus on the production of electric trucks. This decision was made in an effort to bring down prices for U.S. buyers and to compete with Chinese EV makers on the global market. The move comes as a response to the increasing demand for affordable electric vehicles, with the market being dominated by Chinese manufacturers. Ford's goal is to provide American consumers with a more affordable option for electric trucks, as well as increase their competitiveness on the global stage.

Challenges in the Electric Truck Market

Ford's decision to focus on electric trucks comes with its own set of challenges. One of the main obstacles is the high cost of battery production, which is a major factor in the overall price of electric vehicles. Ford will have to find ways to reduce these costs in order to offer a more affordable option for consumers. Additionally, the company will have to overcome the current infrastructure limitations for electric vehicles, as well as the skepticism of some American buyers towards electric trucks.

The Future of Electric Trucks

Despite these challenges, Ford's move towards electric trucks is a significant step in the right direction. With the increasing demand for environmentally friendly transportation, the market for electric trucks is expected to grow in the coming years. By offering a more affordable option, Ford has the potential to not

About the Organizations Mentioned

Ford

## Overview Ford Motor Company is a global automotive industry leader, recognized as the second-largest automaker in the United States (after General Motors) and the sixth-largest worldwide[1]. Headquartered in Dearborn, Michigan, Ford designs, manufactures, markets, and services a full line of vehicles—including cars, trucks, SUVs, electrified vehicles, and luxury vehicles under the Lincoln brand[1]. The company operates in every major automotive market and is renowned for its innovation, manufacturing scale, and iconic brands. ## History and Key Achievements Founded in 1903 by Henry Ford, the company revolutionized the automotive industry with the introduction of the Model T in 1908, making cars affordable for the masses through assembly line production. This innovation not only transformed Ford but also set a new standard for industrial manufacturing worldwide. Over more than a century, Ford has introduced several landmark vehicles, such as the F-Series trucks—America’s best-selling vehicle for over four decades—and the Mustang, an enduring symbol of American automotive culture[1]. ## Current Status As of 2025, Ford continues to demonstrate strong financial performance, with revenues of $185 billion and net profits of $5.9 billion in 2024[1]. The company is led by CEO Jim Farley, who has prioritized both electrification and quality improvements since taking the helm in 2020[1]. Ford’s vehicle lineup remains robust, with the F-Series leading U.S. truck sales and electrified vehicles accounting for nearly 16% of its U.S. sales in the third quarter of 2025[3]. The company is aggressively investing in electric vehicles (EVs), committing $5 billion to develop a family of affordable, adaptable EVs and building a new battery plant in Michigan[2]. ## Notable Aspects and Challenges Ford is currently at a pivotal moment in its history. It is reinventing its manufacturing system to produce next-generation EVs, aiming to secure American jobs

Louisville Assembly Plant

The **Louisville Assembly Plant (LAP)** is a major Ford Motor Company vehicle production facility located on Fern Valley Road in Louisville, Kentucky. Opened in **1955**, it spans over **3.15 million square feet** on a **180-acre** site near Louisville International Airport, employing about **4,610 workers** operating three shifts[1][6]. LAP has been central to Ford’s vehicle assembly in the region for over seven decades, reflecting the evolution of the American automotive industry. Historically, Ford’s Louisville operations began in **1913** with small assembly shops on South Third Street, gradually expanding through several plants before settling at the current LAP site in 1955[1][2][5]. The plant initially produced a broad range of vehicles, including the **ill-fated Edsel line (1957-59)**, notable for constituting about 67% of Edsel production[1][6]. Over the years, LAP shifted focus from passenger cars to light trucks and SUVs, reflecting market trends. Key milestones include the 1969 spin-off of heavy truck production to the separate **Kentucky Truck Plant**[1][2][3], the introduction of popular models such as the **Ford Ranger and Bronco II in the 1980s**[1], and the early 1990s debut of the **Ford Explorer**, a pivotal model for Ford’s SUV lineup, with production continuing into the 2000s[1][3]. The 2010s saw LAP transition to producing the **Ford Escape** and luxury **Lincoln MKC and Corsair SUVs**, highlighting its adaptability to changing consumer preferences and technology[1]. LAP has also faced challenges, notably near-closure threats during economic downturns, but local leadership, unions, and Ford management successfully negotiated reinvestment agreements, preserving its role[5]. Looking ahead, LAP is scheduled for a significant remodel in late 2025 to prepare for **electri